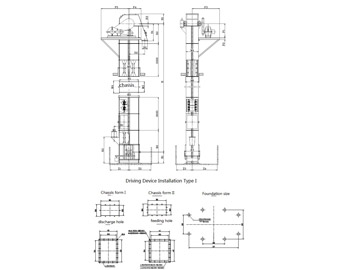

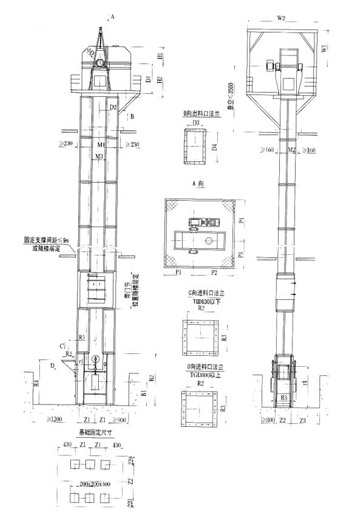

NE 시리즈 체인 엘리베이터는 광석, 석탄, 시멘트, 시멘트 클링커, 곡물, 화학 비료 등과 같은 모든 종류의 재료를 들어 올리는 데 널리 사용되는 국내 고급 수직 리프팅 장비의 일종입니다. NE 시리즈 체인 버킷 엘리베이터는 주로 작업 부품, 구동 장치, 상부 장치, 중앙 케이싱, 하부 장치로 구성됩니다.

NE 시리즈 체인 엘리베이터의 성능 및 특성:

| Model |

lifting capacity |

Material Max.Lumpiness |

||||

| percentage(%) |

||||||

| 10 |

25 |

50 |

75 |

100 |

||

| NE15 |

15 |

65 |

50 |

40 |

30 |

25 |

| NE30 |

32 |

90 |

75 |

58 |

47 |

40 |

| NE50 |

60 |

90 |

75 |

58 |

47 |

40 |

| NE100 |

110 |

130 |

105 |

80 |

65 |

55 |

| NE150 |

165 |

130 |

105 |

80 |

65 |

55 |

| NE200 |

220 |

170 |

135 |

100 |

85 |

70 |

| NE300 |

320 |

170 |

135 |

100 |

85 |

70 |

| NE400 |

440 |

205 |

165 |

125 |

105 |

90 |

| NE500 |

470 |

240 |

190 |

145 |

120 |

100 |

| NE600 |

600 |

240 |

190 |

145 |

120 |

100 |

| NE800 |

800 |

275 |

220 |

165 |

135 |

110 |

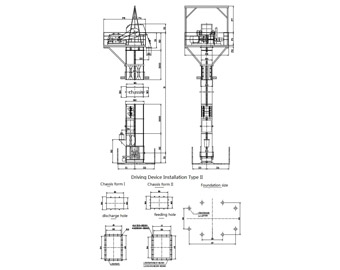

TGD 타입 벨트 버킷 엘리베이터는 전 세계적으로 차세대 첨단 엘리베이터입니다. TGD 엘리베이터는 특히 건축 자재, 야금, 화학, 식품, 전기 산업 등의 산업에서 건조 분말 재료 또는 입상 재료 등을 수직으로 들어 올리는 데 적합합니다. NSP 시멘트 공장의 원료, 원료 균질화 사일로, 시멘트 저장 사일로에 이상적인 리프팅 제품입니다.

TDG 시리즈 체인 엘리베이터의 성능 및 특성:

| model specification | TGD 315P | TGD 315 | TGD 400 | TGD 500 | TGD 630 | TGD 800 | TGD 1000 | TGD 800 | TGD 1000 | TGD 1250 | TGD 1400 | TGD 1600 | ||

| Bucket Specifications | Bucket width (mm) | 315 | 400 | 400 | 500 | 630 | 800 | 1000 | 800 | 1000 | 1250 | 1400 | 1600 | |

| Bucket volume (dm3) | 6.6 | 10.0 | 14.5 | 18.0 | 29.3 | 37.3 | 46.6 | 46.0 | 58.0 | 72.7 | 99.0 | 114.0 | ||

| Bucket speed (m/s) | 1.31 | 1.50 | 1.6 | 1.98 | ||||||||||

| Cylinder diameter (mm) | 630 | 800 | 1000 | 1250 | ||||||||||

| Theoretical capacity (m3/h)

|

Interspace Bucket (mm)

|

280 | 111 | 168 |

|

|

|

|

|

|

|

|

|

|

| 320 | 97 | 147 | 244 | 303 |

|

|

|

|

|

|

|

|

||

| 360 | 86 | 131 | 217 | 270 | 460 | 585 | 731 |

|

|

|

|

|

||

| 400 |

|

|

195 | 243 | 414 | 527 | 658 | 815 | 1028 | 1289 |

|

|

||

| 440 |

|

|

178 | 221 | 376 | 479 | 598 | 741 | 935 | 1172 | 1596 | 1837 | ||

| 480 |

|

|

|

|

345 | 439 | 548 | 679 | 857 | 1074 | 1463 | 1684 | ||

| 520 |

|

|

|

|

318 | 405 | 506 | 627 | 791 | 992 | 1350 | 1555 | ||

| 550 |

|

|

|

|

301 | 383 | 478 | 593 | 748 | 937 | 1277 | 1470 | ||

분말 재료의 공압 이송은 고압 이송, 중압 이송, 저압 이송으로 나눌 수 있습니다.

저압 공압 이송에는 에어 슈트 이송과 파이프라인 음압 이송이 포함됩니다. 필요한 공기압은 일반적으로 루츠 블로어와 원심 팬을 구동 동력으로 사용하는 6KPa 미만입니다. 파이프라인 공압 이송은 저밀도 상 공압 이송과 희석 상 공압 이송으로 나눌 수 있으며, 가스-물질 비율(kg/m3)에 따라 분류됩니다.

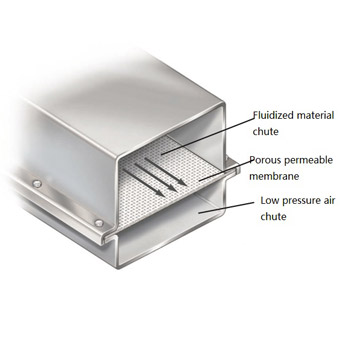

에어 슈트는 건조 분말 재료를 운반하는 데 널리 사용되는 일종의 공압식 이송 장비로, 시멘트 산업에서 시멘트와 원료 분말을 운반하는 데 일반적으로 사용됩니다.

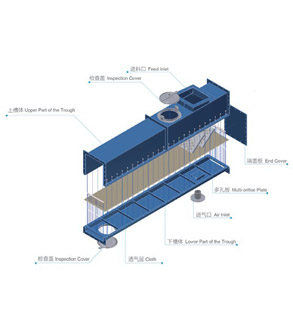

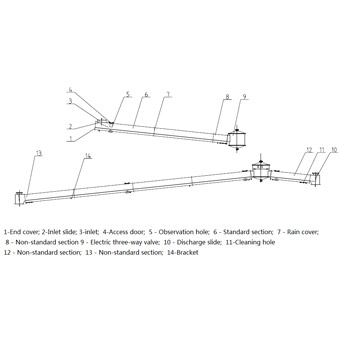

에어 슈트는 다른 액세서리와 함께 볼트로 고정된 여러 개의 강철 슈트로 만들어지며, 에어 슈트의 상부와 하부 쉘 사이에 가스 투과성 층이 있습니다. 일반적으로 에어 슈트는 공급, 표준, 비표준, 차단 밸브, 곡선 홈, T-슬롯, 커버, 배출 슬라이더, 공기 공급 및 지지 구조로 구성됩니다.

SRON 에어 슈트의 장점:

재료 운송: 수분 함량 및 레; 1% 건조 분말 재료, 온도 ≤ 150°C.

각도: 4°, 6°, 8°, 10° 및 12°

(재료가 다른 경우 각도도 달라야 합니다. 같은 종류의 재료의 경우 수분 함량이 많으면 큰 각도를 선택해야 합니다. 일반적으로 배치 조건에 따라 큰 딥 각도가 운반에 좋습니다.)

| specification | XZ200 | XZ250 | XZ315 | XZ400 | XZ500 | XZ630 | XZ800 | |||

| suit width | mm | 200 | 250 | 315 | 400 | 500 | 630 | 800 | ||

| dose delivery | 4° | cement | t/h | 22 | 40 | 70 | 130 | 220 | 320 | 400 |

| Raw material | 16 | 30 | 55 | 100 | 165 | 245 | 310 | |||

| 6° | cement | 40 | 65 | 120 | 250 | 400 | 610 | 765 | ||

| Raw material | 30 | 55 | 90 | 185 | 300 | 455 | 565 | |||

| 8° | cement | 50 | 80 | 140 | 300 | 470 | 720 | 900 | ||

| Raw material | 35 | 65 | 110 | 225 | 355 | 540 | 670 | |||

| 10° | cement | 60 | 100 | 170 | 380 | 570 | 900 | 1080 | ||

| Raw material | 45 | 80 | 140 | 285 | 425 | 670 | 800 | |||

| 12° | cement | 70 | 120 | 205 | 455 | 685 | 1080 | 1295 | ||

| Raw material | 50 | 95 | 165 | 340 | 510 | 805 | 960 | |||

| suit section length | standard section | mm | 2000 | |||||||

| non-standard section | mm | 250 | ||||||||

| atmospheric pressure | KPa | 4-5.5 | ||||||||

| air consumption | M3/m2.min | 1.5-2 | ||||||||

| gas permeable layer | ingredient | synthetic fiber | ||||||||

| thickness | mm | 4-6 | ||||||||

| temperature resistance | ℃ | 150 | ||||||||

| Radial breaking strength | N/cm width | 4700 | ||||||||

| resistance | Pa | 800-1200 (M3/m2.min under conditions) | ||||||||

아래 양식으로 문의 해주십시오. 24 시간 내에 답변을 드리겠습니다.

장비의 각 부분을 엄격하게 관리하면 세부 사항이 완벽 해집니다.